Stairs

Basement Stairs

Unigus delivered the stair stringers and the metal grating treads on Good Friday just in time for the long three day weekend!

Sunday, April 24, 2011

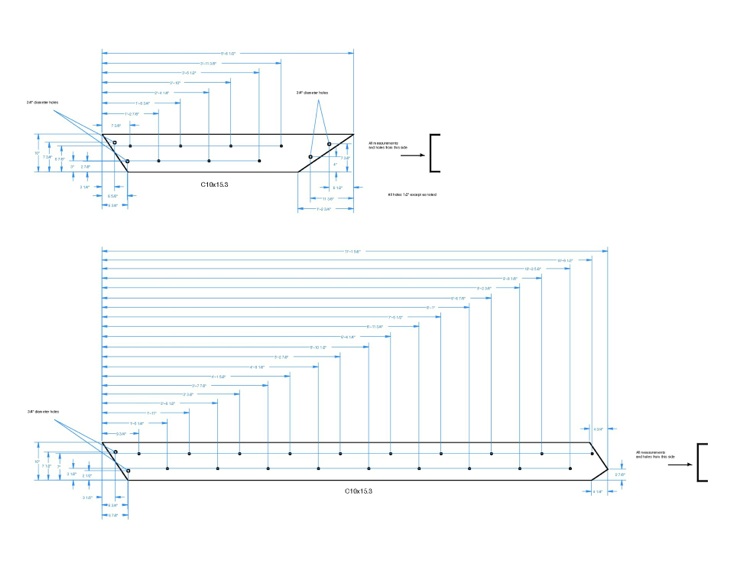

I drew the stairs with TurboCAD on OSX, extracted the two stringers (complete with holes to attach the treads) and added dimensions. Unigus fabricated the two stringers out of structural steel C channels (C10x15.3 - which is a standard C channel, 10 inches wide weighing 15.3 pounds per foot) and the landing out of a 20ft long metal bar grating slab. They also organized getting the standard metal grating stair treads and had them hot dip galvanized.

The long stringer sits on the basement slab and rises up to about 7ft where it is attached to the HSS column with a metal bracket and 1/2” structural bolts. The short stringer is attached to the HSS column on one end and rises up to two steps below the first floor where it is attached to the flange of an I-beam, also with a metal bracket and 1/2” structural bolts. Ray and I fabricated the metal brackets ourselves with 3”x3”x1/3” stock and a drill press (which almost ripped off my finger when the drill caught my gloves. A close call - this weekend wasn’t too good accident wise because I also smashed my right thumb’s nail-bed which bled a lot).

The stairs lead up to a platform, which sits on a frame that I made by welding 2”x3”x1/4” steel angles together. The frame is bolted to the concrete walls with six 3” long 3/8” Tapcons.

There are a total of 16 treads and the platform.

12 treads were simple to install, if not a bit tricky to get the attachment to the concrete wall right (a hammer drill always seems to skip a bit away from the accurate center point).

4 treads were not trivial to attach, two treads at the very top couldn’t be attached to a stringer because they were at the level of an I-beam so we had to weld a custom support frame. Two treads adjacent to the platform had one attachment point inside the column. Due to inaccuracies with the wall, one side of the column was 1/4” too close to the wall and therefore we had to trim a tread and weld it to the column.

I’m very glad that the stair geometry worked out correct because there are code requirements about riser variation and limits that must be met.